Uses: thickness / coating measurement Used in aluminum strip (hot rolling, cold rolling, foil rolling), steel strip (hot rolling, cold rolling), stainless steel, copper and other metals on-line thickness measurement and control; coating (galvanized, tin-plated, galvanized iron, color coating) Plate or other metal) real-time thickness measurement and control.?

- Metal products(Bar/pipe/plate, hot/ cold rolling)production gauging

- Automatic measuring / Measuring speed:1ms/ Accuracy: 1%

- Measurement accuracy close to the German level

- Self calibration

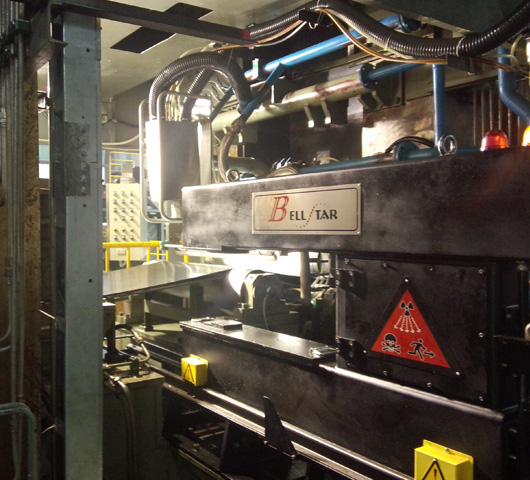

- Metal ceramic ray tube

- Special cooling system design for radiation source protection

- Operation site protection

- Practical measurement precision setting & sampling setting

- Durable & long service life:2/3 longer than avg. (basing on the same environmment)

- Well stock for core components, reduce unplanned downtime.

Site Control Advantage:

- Site synchronous:Microsecond response

- Base on IPC:Industrial PC-PC control,Embedded PC

- Open System:EtherCat fieldbus

- Friendly HMI:smart, clear and adaptable

- Low maintenance cost:base on windows platform

- Data online recording:manufacturing/measuring/operating data uploaded instantly

- Stable process:operation/data synchronous

- Owned intellectual property rights :Flexible configuration to fit industrial site requirement